DTF Print Sheets revolutionize apparel production with direct fabric printing, enabling brands to create high-quality, unique designs for limited edition drops. This technology offers swift production times, cost savings, and enhanced design versatility, especially in custom T-shirt printing. Best practices include using compatible film, precise printing methods, quality control checks, proper heat application, and regular printer maintenance.

“Discover the game-changing potential of DTF Print Sheets in the apparel industry’s dynamic landscape. This innovative technology is transforming limited edition drops, allowing designers and brands to create vibrant, unique pieces with ease.

In this article, we explore the world of DTF (Direct to Fabric) Print Sheets, delving into its benefits for creating exclusive collections. From enhancing quality control to fostering a bustling market, we uncover best practices to ensure success in the competitive realm of limited-edition apparel releases.”

- Understanding DTF Print Sheets for Apparel Drops

- Benefits and Applications in Limited Edition Releases

- Best Practices for Success and Quality Control

Understanding DTF Print Sheets for Apparel Drops

DTF (Direct-to-Fabric) Print Sheets are revolutionizing the way limited edition apparel drops are executed. This cutting-edge technology allows for precise, high-quality printing directly onto fabric, enabling clothing brands to create unique and visually stunning designs with ease. By utilizing DTF transfer sheets, brands can achieve intricate patterns and detailed logos that were previously difficult or impossible to reproduce on garments.

For apparel drops, DTF printing offers several advantages. It facilitates quick turnaround times, allowing brands to meet the high demand for limited-edition pieces. Moreover, it provides a cost-effective solution compared to traditional printing methods, making it accessible for small and emerging clothing labels. With DTF printing for hoodies and other garments, brands can create exclusive collections that capture the attention of their target audience, fostering brand loyalty and driving sales during special drops.

Benefits and Applications in Limited Edition Releases

DTF (Direct to Fabric) Print Sheets offer numerous benefits for limited edition apparel releases, revolutionizing the way designers and manufacturers bring their unique concepts to life. The primary advantage lies in its versatility; DTF printing allows for intricate and detailed designs to be precisely transferred onto various fabric types, enabling brands to create eye-catching, limited-run collections with ease. This method is particularly popular for custom T-shirt printing, where businesses can offer personalized, one-of-a-kind garments to their customers.

By utilizing DTF Print Sheets, apparel companies can streamline their production process and reduce lead times. These sheets are designed for heat pressing, ensuring fast and efficient application of designs onto garments. This technology also facilitates the creation of complex art and graphics with vibrant colors and crisp lines, making it an ideal solution for limited edition releases that demand a high level of detail and uniqueness. Moreover, DTF printing supports customization at scale, allowing brands to cater to individual consumer preferences while maintaining the exclusivity of their limited-edition offerings.

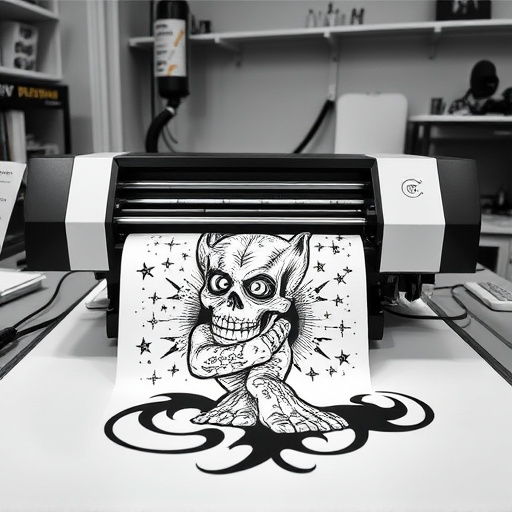

Best Practices for Success and Quality Control

For DTF Print Sheets to be a success for limited edition apparel drops, it’s crucial to establish best practices and maintain rigorous quality control measures. Begin by selecting high-quality DTF transfer film compatible with your dtf printer, ensuring accurate color reproduction and crisp detail on garments. The printing process itself demands precision; use calibrated printers and follow manufacturer guidelines for ink types and application methods to prevent smudging or inconsistencies.

Post-printing, thorough quality control checks are essential. Inspect each sheet for any defects, misprints, or misalignments. Ensure the DTF transfer film is properly heated and applied to garments without bubbles or wrinkles. Regularly clean and maintain your dtf printer to avoid buildup that can affect print quality over time. These meticulous steps will guarantee that your limited edition apparel drops meet high standards and deliver the vibrant, precise designs your customers expect.

DTF (Direct-To-Fabric) print sheets have emerged as a game-changer in the apparel industry, especially for limited edition drops. By understanding their unique benefits and implementing best practices for quality control, brands can create vibrant, exclusive collections that cater to today’s dynamic market. These innovative printing methods revolutionize the way we approach custom apparel, ensuring each drop is a success.